Ultrasonic Gas Flow Measurement

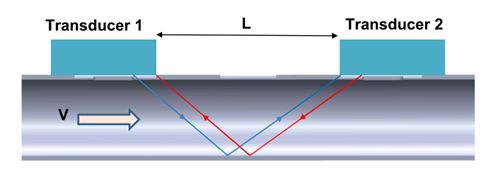

Transit time flowmeters operate on the principle that a sonic pulse is sent from a transmitting transducer, which propagates through the flowing medium to a receiving transducer. Depending on the velocity of the flow, the difference between the times of arrival of a pulse propagated against the flow (upstream direction) and the one propagated with the flow (downstream) is used to calculate the velocity of the flow.

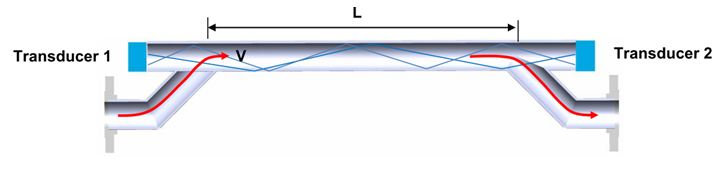

The longer the distance L between the transducers the larger is the time difference, therefore, more accurate measurement can be obtained, in particular for low velocities V. Increasing the number of reflections (W-type sonic path, etc.) does not improve the performance of the device as it actually does not change the initial base length L. This explains the specifics of Lauris’s axial transit-time measurement technique: ultrasonic pulses cross the gas axially with the flow.

Bending the pipe to achieve axial sonic direction affects the flow profile. This negative effect is compensated by the strong averaging effect: the whole cross-section of the pipe is transilluminated with sonic pulses due to high bean divergence in transducers.

The time difference is traditionally measured using cross-correlation technique but Lauris Technologies Inc. has developed a proprietary method for accurate measurement of sonic signals traveled between each pair of transducers.